Upgrading the pump,

replacing the mechanical seal and improving the pump

performance

Khurmankhan

Maral

maral1001@bk.ru

teacher, Pavlodar chemical

and mechanical college, city of Pavlodar,

Kazakhstan

Umurzakova Sabina

Beibitovna

umurzakovasabina@mail.ru

teacher, Pavlodar chemical

and mechanical college, city of Pavlodar,

Kazakhstan

Omarbekova Inara

Kasymkhanovna

inara_19@mail.ru

teacher, Pavlodar chemical

and mechanical college, city of Pavlodar,

Kazakhstan

Annotation:The article deals with issues

related to replacing the mechanical seal of the h-004 pump. In many

ways, single end seals will wear out from mechanical impurities,

and if they are not properly used, which slow down the process and

can allow products to leak.

The purpose of this work is to

eliminate the pulverization of a small fraction of the pumped

product , which occurs in the operation of the pump in

petrochemical processes.

Keywords: centrifugal pump, mechanical

seal, sealing.

In the presidential address

“Kazakhstan 2050”, country leader N. A. Nazarbayev underlined that

the oil and gas complex of Kazakhstan is a locomotive for the

entire economy and contributes to the development of other

industries, that an effective oil and gas sector of the economy

should be created. Due to the development of the share of the

country's oil and gas industry has grown over the past 5 years from

14.7% to 25.8%, which indicates the stable growth dynamics of the

oil and gas industry.

Pavlodar petrochemical plant

is the largest enterprise in Kazakhstan for the production of

petroleum products. MLP "PNHZ " is the only enterprise in

Kazakhstan with a set of technological installations that provides

deep processing of oil up to 85%, which corresponds to the level of

the best producers of petroleum products.

Today, the main goal of the

Pavlodar petrochemical plant is producing demanded products in the

volume necessary for the needs of the country and corresponding to

the requirements of the world market. The main way to achieve this

goal is creating a modern production base as a result of

modernization and technical re-equipment of existing production, as

well as the construction of new high-tech

facilities.

The Isomerization process Unit

and Naphtha Splitter are an integral part of the plant's

production. The isomerization unit and Naphtha Splitter is used to

produce commercial naphtha with an octane number not lower than

88.5, which is a high-octane component of gasoline AI-92-K2,

AI-95-K2, as well as light and heavy naphtha for further

refinements.

Pumping equipment plays a very

large and important role in the life of the plant. Correct and

unyielding operation of pumping equipment is an indispensable

factor in the operation of the entire installation, which allows us

to learn the importance of maintenance, installation and proper

operation of pumps.

The object of research is a

cantilever centrifugal pump N-004 of the USP40-380 type of

isomerization unit and a naphtha Splitter.

Pumps are hydraulic machines

that convert the mechanical energy of the drive motor into the

energy of the fluid flow, which serves to move and supply all types

of liquids. According to the principle of operation, there are:

centrifugal , rotary, piston, screw, and there are also special

pumps. These include: electromagnetic, pneumatic, and so

on.

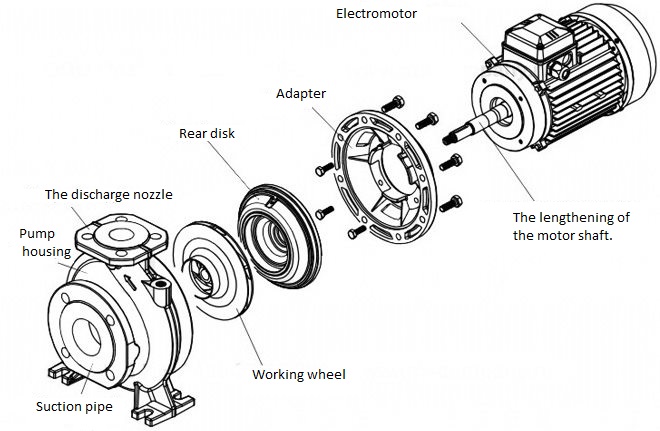

Centrifugal pumps are units

consisting of a shell in the form of a snail and an electric motor,

connected by a gear coupling and mounted on a common Foundation

plate, which have suction and discharge pipes. The main working

body is the impeller mounted on a shaft that is connected to the

electric motor via a plate coupling.

In our time, oil and gas

equipment failure often occurs, at this stage, consider the

horizontal cantilever single-stage centrifugal pump H-004 model

USP40-380 isomerization unit and naphtha Splitter. Pump N-004 model

USP40-380, technological position A100-N-004A, is designed for the

circulation of alkali in the K-002 column.

Main parts of the centrifugal

pump

The lion's share of all pumps

produced in the world are console pumps of various types and

designs. According to experts published at various times in

specialized publications related to pumping topics, the number of

console pumps in pieces is from 59 to 72% of the total fleet of

pumps produced in the world. This figure is due to the simple

design of the cantilever pump compared to other types of pumps. The

elementary principle of the cantilever pump ensures its wide

distribution both in municipal equipment and in complex liquid

supply systems of military equipment and

spacecraft.

Console pumps have long proven

themselves only on the positive side. Their external simplicity

bribes the future owner. But behind this simplicity lies a

universal device that is ready to perform any tasks. The cantilever

pump is designed for pumping liquid in both cold and hot

conditions. An important and distinctive feature is that the

composition of the pumped liquid may include impurities. Their

concentration should not exceed 0.1%. Given the relatively high

productivity, this figure is actually very high. The size of some

solid particles is limited to 0.2 mm.

An alkaline NaOH solution from

the bottom of the K-002 column is fed to the suction of the

h-004A/B alkali circulation pumps. After pumping the pumps, passing

the heater T-012, the alkali is distributed into two streams. The

first flow is supplied from above the bottom of the nozzle where

the dry gas is washed with an alkaline solution, the second stream

is fed below the bottom part of the bottom nozzle of the column to

the spray nozzle to protect the column from contact with corrosive

gas by washing the walls of the scrubber an alkaline

solution.

The temperature of the alkali

at the outlet of the heater T-012 is controlled by the device POS.

TIA-0096.

If the concentration of the

circulating alkaline solution decreases below 2% (wt.) NaOH, the

spent alkali from the h-004A pumps/B is sent to the waste alkali

degassing tank E-009.

Our idea is to replace a

single mechanical seal with a double mechanical seal. Why at this

time, from this pump through water flushing come out in small

fractions of alkali? The answer is as follows: since we know that a

centrifugal cantilever pump when pumping an alkaline solution has

mechanical impurities in the composition of the product being

pumped.

Currently, the cantilever type

of centrifugal pumps is considered the most advanced in the field

of high performance.Among the total volume of pumping equipment

produced, console-type pumps account for 65 %. These units have

gained popularity due to their very simple design, ease of repair

and maintenance, and fairly high

efficiency.

By its design, the cantilever

pump is a type of centrifugal pump, which is characterized by the

presence of a working centrifugal wheel.

The main advantages of the

cantilever pump housing design, which allows installation of the

pressure pipe vertically and horizontally, are the

following:

- direct attachment of the

flanged motor to the pump body (provides the least impact of

vibration on the structure);

- the presence of a mechanical

seal, independent of the direction of rotation (provides ease of

operation);

- the possibility of quick

start and fast stop of the pump operation;

- high characteristics of

vibroacoustics (reduced noise level).

Based on the General situation

and based on the totality of all the above-mentioned facts, we can

determine: when pumping the product, a single mechanical seal does

not sufficiently seal the pumping medium, and replacing the double

mechanical seal will eliminate the pulverization of a small

fraction of the alkaline solution.

Based on the evidence, we can

draw the following conclusion. Double mechanical seal is the best

replacement for improved performance and impermeability through

o-rings.

The double mechanical seal

will last much longer, since the new SBTU cooling system will be

operated during the water wash process and will perform more

thorough sealing, as well as deep cooling and detailed lubrication.

The seal will allow the pump to operate for a long

time.

List of sources

used

1. Chisholm R. Techniques of vibration

analysis to gas turbines. / R. Chisholm. – Gas turbine Int. – № 6.

– 1979.P. 170 – 200.

2. Dunton T.A. An Introduction to Time

Waveform Analysis. / T.A. Dunton. – Universal Technologies. – 1999.

P. 120 – 128.

3. Jones C.M. Pumping station design

/ С. M. Jones. - Pumping station design. – 2006.

P. 20 – 24.

4. Ryndin V. V. Application of

the Mathcad system for static analysis of experimental data / V.

Ryndin, Yu. Volkova / / Science and technology of Kazakhstan. -

2008. Р. 95.

5. Perevoschikov S. I.

Reduction of hydrodynamic vibration of centrifugal

pumps.– 1997. P.

50–56.

Дайын ҚМЖ. Барлық пәндерден 2022-2023 оқу жылына, жаңа бұйрыққа сай жасалған

Дайын ҚМЖ. Барлық пәндерден 2022-2023 оқу жылына, жаңа бұйрыққа сай жасалған