![]()

![]()

Nanoparticles

1

accomplish using most of the other

nanofabrication techniques. New advances in chemical vapor deposition such as ‘initiated chemical vapor deposition’ (i-CVD) provide unprecedented opportunities of depositing polymers without reduction in the molecular weights

Allows high-precision assembling of Many issues need to explore, such as Very early stage. Ultimate success nanoscale components into novel unit and integration processes, depends on the willingness of the programmable arrangements with compatibility with CMOS fabrication, semiconductor industry in terms of much smaller dimensions (less than line edge roughness, throughput and need, infrastructural capital investment, 10 nm in half-pitch) cost yield and manufacturing cost

DNA-

scaffolding

materials including metal, ceramics,

semiconductors, insulators and polymers, high purity nanofilms, a scalable process, possibility to deposit porous nanofilms

General remarks

Demerits

Merits

Bottom–up

method

Table 1 (continued)

-

Characterization of NPs 915

-

Morphological characterizations 915

-

Structural characterizations 916

-

Particle size and surface area characterization 918

-

Optical characterizations 919

-

Characterization of NPs

Different characterization techniques have been practiced for the analysis of various physicochemical properties of NPs. These include techniques such as X-ray diffraction (XRD), X-ray photoelectron spectroscopy (XPS), infrared (IR), SEM, TEM, Brunauer–Emmett–Teller (BET), and particle size analysis.

-

Morphological characterizations

The morphological features of NPs always attain great interest since morphology always influences most of the properties of the NPs. There are different characterization techniques for

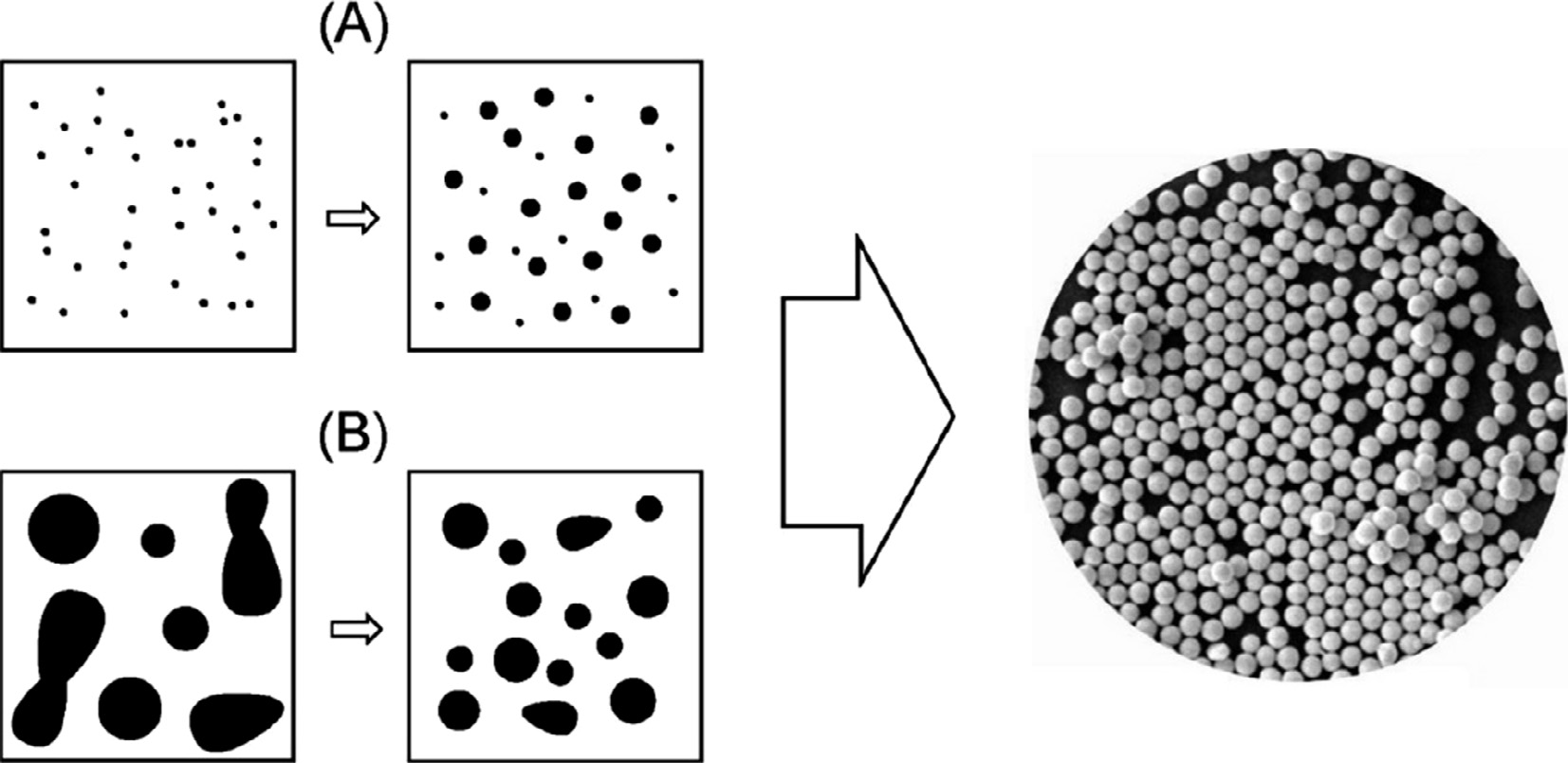

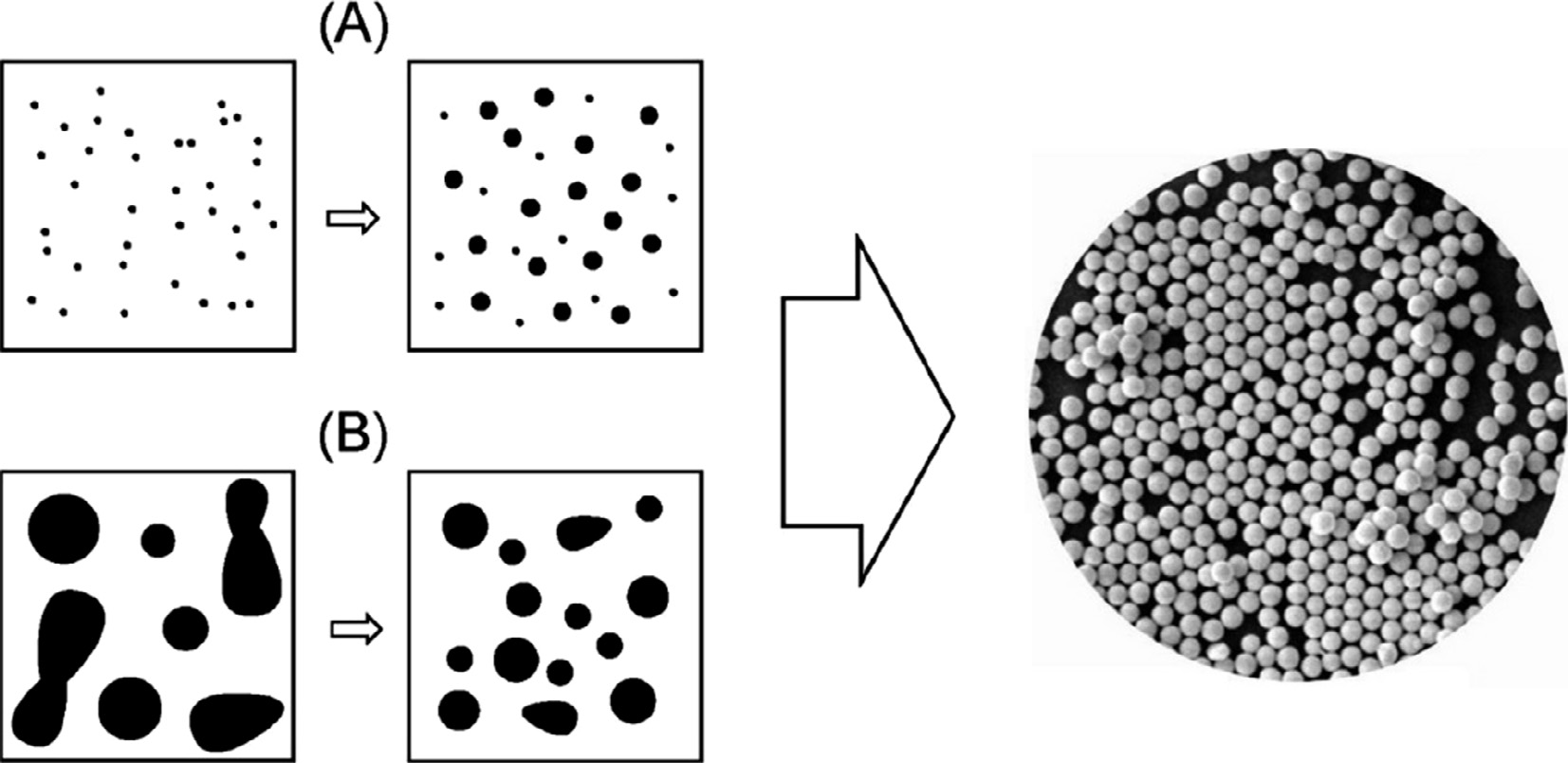

Scheme 3 (A) Bottom-up approach: A molecular precursor is disintegrated to simpler metal atoms that grow into colloids. (B) Top- down approach: Large drops of a metal broken into smaller drops (Wang and Xia, 2004).

morphological studies, but microscopic techniques such as polarized optical microscopy (POM), SEM and TEM are the most important of these.

SEM technique is based on electron scanning principle, and it provides all available information about the NPs at nanos- cale level. Wide literature is available, where people used this technique to study not only the morphology of their nanoma- terials, but also the dispersion of NPs in the bulk or matrix. The dispersion of SWNTs in the polymer matrix poly(buty- lene) terephthalate (PBT) and nylon-6 revealed through this technique (Saeed and Khan, 2016, 2014). The same group also provides POM study of their materials, which showed star-like spherulites of the formed materials, whose size was decreased with the incremental filling of SWNTs. The morphological fea- tures of ZnO modified metal organic frameworks (MOFs) were studied through SEM technique, which indicates the ZnO NPs dispersion and morphologies of MOFs at different reaction conditions (Fig. 7) (Mirzadeh and Akhbari, 2016).

Similarly, TEM is based on electron transmittance princi- ple, so it can provide information of the bulk material from very low to higher magnification. The different morphologies of gold NPs are studied via this technique. Fig. 8 provides some TEM micrographs showing various morphologies of gold NPs, prepared via different methods (Khlebtsov and Dykman, 2011, 2010a, 2010b). TEM also provides essential information about two or more layer materials, such as the quadrupolar hollow shell structure of Co3O4 NPs observed through TEM. These NPs founded to be exceptionally active as anode in Li-ion batteries (Fig. 9). Porous multishell struc- ture induces shorter Li+ diffusion path length with adequate annulled space to buffer the volume expansion, good cycling performance, greater rate capacity, and specific capacity as well (Wang et al., 2013).

-

Structural characterizations

The structural characteristics are of the primary importance to study the composition and nature of bonding materials. It pro- vides diverse information about the bulk properties of the sub-

ject material. XRD, energy dispersive X-ray (EDX), XPS, IR, Raman, BET, and Zieta size analyzer are the common tech- niques used to study structural properties of NPs.

XRD is one of the most important characterization tech- niques to reveal the structural properties of NPs. It gives enough information about the crystallinity and phase of NPs. It also provides rough idea about the particle size through Debye Scherer formula (Khan et al., 2017b, 2017c; Ullah et al., 2017). This technique worked well in both single and multiphase NPs identification (Emery et al., 2016). Never- theless, in the case of smaller NPs having size less than hun- dreds of atoms, the acquisition and correct measurement of structural and other parameters may be difficult. Moreover, NPs having more amorphous characteristics with varied inter atomic lengths can influence the XRD diffractogram. In that case, proper comparison of the diffractograms of bimetallic NPs with those of the corresponding monometallic NPs and their physical mixtures is required to obtain accurate informa- tion. Comparison of computer simulated structural model of bimetallic NPs with observed XRD spectra is the best way to get good contrast (Ingham, 2015). EDX, which is normally fixed with field emission scanning electron miscopy (FE-SEM) or TEM device is widely used to know about the elemental composition with a rough idea of % wt. The electron beam focused over a single NP by SEM or TEM through the pro- gram functions, to acquire the insight information from the NP under observation. NP comprises of constituent elements and each of them emits characteristics energy X-rays by elec- tron beam irradiation. The intensity of specific X-ray is directly proportional to the concentration of the explicit element in the particle. This technique is widely used by researchers to give support to SEM and other techniques for the confirmation of their elements in prepared materials (Avasare et al., 2015; Iqbal et al., 2016). The EDX technique used to determine the elemental composition of ultra-sonochemically synthesized pseudo-flower shaped BiVO4 NPs (Khan et al., 2017b). Simi- larly, by utilizing similar technique the elemental confirmation and graphene impregnation of In2O3/graphene heterostructure NPs was carried out, which showed C, In and O as contribut-

Table 1 Top-down and bottom-up synthetic techniques with merits, demerits and general remarks (Biswas et al., 2012).

Top–down method

Merits Demerits General remarks

Optical lithography

E-beam lithography

Soft and nanoimprint lithography

Block co- polymer lithography

Scanning probe lithography

Long-standing, established micro/nanofabrication tool especially for chip production, sufficient level of resolution at high throughputs

Popular in research environments, an extremely accurate method and effective nanofabrication tool for <20 nm nanostructure fabrication with desired shape

Pattern transfer based simple, effective nanofabrication tool for fabricating ultra-small features (<10 nm)

A high-throughput, low-cost method, suitable for large-scale densely packed nanostructures, diverse shapes of nanostructures, including spheres, cylinders, lamellae possible to fabricate including parallel assembly

High resolution chemical, molecular and mechanical nanopatterning capabilities, accurately controlled nanopatterns in resists for transfer to silicon, ability to manipulate big molecules and individual atoms

Tradeoff between resist process sensitivity and

жүктеу мүмкіндігіне ие боласыз

Бұл материал сайт қолданушысы жариялаған. Материалдың ішінде жазылған барлық ақпаратқа жауапкершілікті жариялаған қолданушы жауап береді. Ұстаз тілегі тек ақпаратты таратуға қолдау көрсетеді. Егер материал сіздің авторлық құқығыңызды бұзған болса немесе басқа да себептермен сайттан өшіру керек деп ойласаңыз осында жазыңыз

Нанотехнология

Нанотехнология

![]()

![]()

Nanoparticles

1

accomplish using most of the other

nanofabrication techniques. New advances in chemical vapor deposition such as ‘initiated chemical vapor deposition’ (i-CVD) provide unprecedented opportunities of depositing polymers without reduction in the molecular weights

Allows high-precision assembling of Many issues need to explore, such as Very early stage. Ultimate success nanoscale components into novel unit and integration processes, depends on the willingness of the programmable arrangements with compatibility with CMOS fabrication, semiconductor industry in terms of much smaller dimensions (less than line edge roughness, throughput and need, infrastructural capital investment, 10 nm in half-pitch) cost yield and manufacturing cost

DNA-

scaffolding

materials including metal, ceramics,

semiconductors, insulators and polymers, high purity nanofilms, a scalable process, possibility to deposit porous nanofilms

General remarks

Demerits

Merits

Bottom–up

method

Table 1 (continued)

-

Characterization of NPs 915

-

Morphological characterizations 915

-

Structural characterizations 916

-

Particle size and surface area characterization 918

-

Optical characterizations 919

-

Characterization of NPs

Different characterization techniques have been practiced for the analysis of various physicochemical properties of NPs. These include techniques such as X-ray diffraction (XRD), X-ray photoelectron spectroscopy (XPS), infrared (IR), SEM, TEM, Brunauer–Emmett–Teller (BET), and particle size analysis.

-

Morphological characterizations

The morphological features of NPs always attain great interest since morphology always influences most of the properties of the NPs. There are different characterization techniques for

Scheme 3 (A) Bottom-up approach: A molecular precursor is disintegrated to simpler metal atoms that grow into colloids. (B) Top- down approach: Large drops of a metal broken into smaller drops (Wang and Xia, 2004).

morphological studies, but microscopic techniques such as polarized optical microscopy (POM), SEM and TEM are the most important of these.

SEM technique is based on electron scanning principle, and it provides all available information about the NPs at nanos- cale level. Wide literature is available, where people used this technique to study not only the morphology of their nanoma- terials, but also the dispersion of NPs in the bulk or matrix. The dispersion of SWNTs in the polymer matrix poly(buty- lene) terephthalate (PBT) and nylon-6 revealed through this technique (Saeed and Khan, 2016, 2014). The same group also provides POM study of their materials, which showed star-like spherulites of the formed materials, whose size was decreased with the incremental filling of SWNTs. The morphological fea- tures of ZnO modified metal organic frameworks (MOFs) were studied through SEM technique, which indicates the ZnO NPs dispersion and morphologies of MOFs at different reaction conditions (Fig. 7) (Mirzadeh and Akhbari, 2016).

Similarly, TEM is based on electron transmittance princi- ple, so it can provide information of the bulk material from very low to higher magnification. The different morphologies of gold NPs are studied via this technique. Fig. 8 provides some TEM micrographs showing various morphologies of gold NPs, prepared via different methods (Khlebtsov and Dykman, 2011, 2010a, 2010b). TEM also provides essential information about two or more layer materials, such as the quadrupolar hollow shell structure of Co3O4 NPs observed through TEM. These NPs founded to be exceptionally active as anode in Li-ion batteries (Fig. 9). Porous multishell struc- ture induces shorter Li+ diffusion path length with adequate annulled space to buffer the volume expansion, good cycling performance, greater rate capacity, and specific capacity as well (Wang et al., 2013).

-

Structural characterizations

The structural characteristics are of the primary importance to study the composition and nature of bonding materials. It pro- vides diverse information about the bulk properties of the sub-

ject material. XRD, energy dispersive X-ray (EDX), XPS, IR, Raman, BET, and Zieta size analyzer are the common tech- niques used to study structural properties of NPs.

XRD is one of the most important characterization tech- niques to reveal the structural properties of NPs. It gives enough information about the crystallinity and phase of NPs. It also provides rough idea about the particle size through Debye Scherer formula (Khan et al., 2017b, 2017c; Ullah et al., 2017). This technique worked well in both single and multiphase NPs identification (Emery et al., 2016). Never- theless, in the case of smaller NPs having size less than hun- dreds of atoms, the acquisition and correct measurement of structural and other parameters may be difficult. Moreover, NPs having more amorphous characteristics with varied inter atomic lengths can influence the XRD diffractogram. In that case, proper comparison of the diffractograms of bimetallic NPs with those of the corresponding monometallic NPs and their physical mixtures is required to obtain accurate informa- tion. Comparison of computer simulated structural model of bimetallic NPs with observed XRD spectra is the best way to get good contrast (Ingham, 2015). EDX, which is normally fixed with field emission scanning electron miscopy (FE-SEM) or TEM device is widely used to know about the elemental composition with a rough idea of % wt. The electron beam focused over a single NP by SEM or TEM through the pro- gram functions, to acquire the insight information from the NP under observation. NP comprises of constituent elements and each of them emits characteristics energy X-rays by elec- tron beam irradiation. The intensity of specific X-ray is directly proportional to the concentration of the explicit element in the particle. This technique is widely used by researchers to give support to SEM and other techniques for the confirmation of their elements in prepared materials (Avasare et al., 2015; Iqbal et al., 2016). The EDX technique used to determine the elemental composition of ultra-sonochemically synthesized pseudo-flower shaped BiVO4 NPs (Khan et al., 2017b). Simi- larly, by utilizing similar technique the elemental confirmation and graphene impregnation of In2O3/graphene heterostructure NPs was carried out, which showed C, In and O as contribut-

Table 1 Top-down and bottom-up synthetic techniques with merits, demerits and general remarks (Biswas et al., 2012).

Top–down method

Merits Demerits General remarks

Optical lithography

E-beam lithography

Soft and nanoimprint lithography

Block co- polymer lithography

Scanning probe lithography

Long-standing, established micro/nanofabrication tool especially for chip production, sufficient level of resolution at high throughputs

Popular in research environments, an extremely accurate method and effective nanofabrication tool for <20 nm nanostructure fabrication with desired shape

Pattern transfer based simple, effective nanofabrication tool for fabricating ultra-small features (<10 nm)

A high-throughput, low-cost method, suitable for large-scale densely packed nanostructures, diverse shapes of nanostructures, including spheres, cylinders, lamellae possible to fabricate including parallel assembly

High resolution chemical, molecular and mechanical nanopatterning capabilities, accurately controlled nanopatterns in resists for transfer to silicon, ability to manipulate big molecules and individual atoms

Tradeoff between resist process sensitivity and

шағым қалдыра аласыз